In our last newsletter, we asked a question: “What label printer and labels do you use for your slab inventory?”

We received some very thoughtful replies. There wasn’t a consensus, but I’ll start with a recommendation from our friend Scott Edwards at DataBridge Integrations – Scott’s been dealing with barcoding and labels for decades, so his words should carry extra weight – if you’re wondering what to use, trusting Scott is probably a good place to start. He typically recommends:

… the Zebra GK420T thermal transfer label printer with Z-Ultimate 3000 poly labels with high-tack adhesive. They are weather proof and stick quite well to the rough narrow edge as they do to the smooth surface of the slabs. Additionally they come off nicely without leaving an adhesive residue.

Again, I suggest reaching out to Scott if you want a deeper conversation on these matters. Some of his customers chimed in as well with the same recommendation.

In no particular order, here are some other interesting replies:

Custom perforated poly tags (some kind of plastic water resistant) ordered in rolls of 2500 … and the Zebra GK420T thermal transfer label printer with performance thermal transfer resin for water and temperature resistance (-20 to +35 Celsius). I seem to remember we spent almost 1 month researching and trialing out different media types with different adhesives to find something that would stick to the rough edge of a granite slab but decided on using silicone with the poly tags rather than sticky labels. Fun times …

We use a “Rhino 5200” label maker because our slabs are outside in frigid weather. We use silicone to adhere them to the stone. They’re very expensive, but we’ll change products this spring when we open our indoor sales office.

We have 2 different label printers: WASP WPL 305 & Zebra GK420T. They both work very well. Our labels are 3″ x 1″ – perfect to place on the side of slabs.

7.5pt plastic card tag on 8 1/2 x 11 sheets perforated to 22 per sheet printed on a laser printer and affixed with silicone.

Dymo LabelWriter 450. Labels 30256. This label has enough room for the supplier name, slab color and size, the job number and name, the purchase order number, slab batch number, serial number, and our location.

Dymo 450 Turbo or 450 Duo. Label: LW 30256 . Size: 2 5/16″ x 4″

We use a Brother PT2430 printer for our labels Our remnants sit outside so the labels need to be laminated.

P-Touch (by Brother) labeler with Sales Order # and Client Name

We use a brother label maker but it is cumbersome … I am interested in hearing what others are using that works better.

I hope you found this information useful … if so, we’ll ask another question next month.

UPDATE 7/28/2016: In response to a comment on this page, Flav Rusu from Natural Stone City was kind enough to get more information about his solution (the first mentioned, above):

I just heard back from my supplier on the tag stock that I am using with the Zebra GK420T thermal transfer printer. The supplier is:

Data Communications Management

Account Rep: Matt MacDonald

1-866-709-7688

https://www.datacm.com

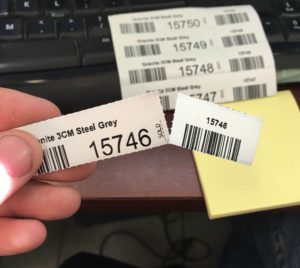

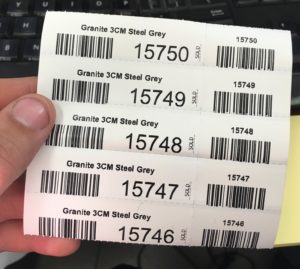

The tags were custom tags 4″ wide by 3/4″ tall with horizontal and vertical perforations and black marks on the back.

Since it was a custom order, if someone else wants these tags they will have to call in and say they want the same tags that Natural Stone City ordered.

I’ve attached photos of what the tags look like after printing. We have a vertical perforation to tear the bottom of the tag off if the slab is sold to a customer.

We print them directly from JobTracker using a custom template (also attached, here).

Just an FYI, the difference between a label and a tag is that a label has adhesive on the back whereas a tag is simply the stock material without glue on the back. In our case we are using silicone as an adhesive.

Thanks for generously sharing this, Flav!