CUSTOMER STORIES: SOUTHEAST STONE

How Southeast Stone Doubled Production Capacity With the Same Workforce

What happens when you get to work and find out your scheduling whiteboard was thrown in the dumpster?

Hear Shayne Hogenmiller, General Manager at Southeast Stone, share how the shop ditched its whiteboard and moved to Moraware leading to more efficiency, boosted profitability, and a significant increase to their production capacity.

Summary

- Scheduling at Scale: The shop relies on Systemize to manage everything from templating, to shop production, to installation scheduling. The increase in efficiency helped the shop double its production capacity.

- Reduced Mistakes: Utilizing Systemize helped track their processes and report on both wins and losses, contributing to reducing errors to a 1% loss rate.

- Improving Team Handoffs: By increasing visibility on key activities and issues in Systemize, team members can quickly address issues and keep jobs on track and on time.

See how thousands of fabricators like Southeast Stone save hours every week with Moraware

The Challenges

Like many fabricators, Southeast Stone initially relied on manual processes, including whiteboards and job folders to manage their operations. This led to stress and long days.

- Static whiteboard: Complete reliance on whiteboards for scheduling created information bottlenecks and outdated job data. It also added risk. If something was accidentally erased, critical information was lost.

- Inefficient communications: Lack of real-time communication between field teams and the office, requiring constant phone calls and interruptions. As the shop grew, everyone needed to be on the same page to avoid costly mistakes.

- Limited reporting and job visibility: No ongoing tracking of job progress, inventory, or insights into reworks and process issues.

The Solution: Job Scheduling and Management with Systemize

In a bold move, the shop owner (and the General Manager’s sister-in-law), threw the scheduling whiteboard in the dumpster and set up the shop with Moraware. After a week of getting ramped up and starting with a basic job tracking, the team saw the benefits, fully embraced the upgrade, and never looked back.

Southeast Stone’s Move from Chaos to Alignment and Efficiency

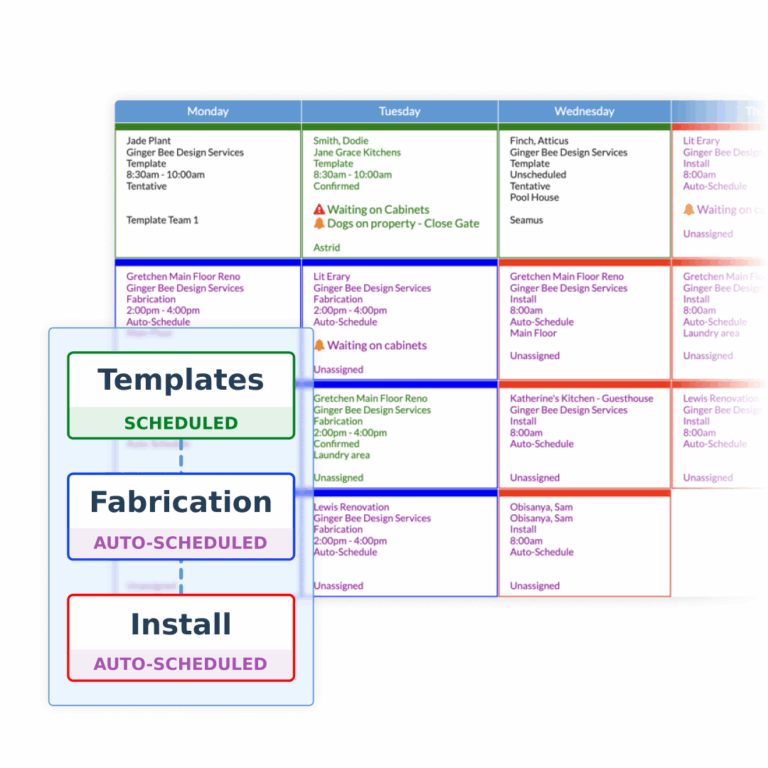

- Streamlined scheduling and workflows: Created detailed workflow tracking with multiple activities and checkpoints for each job from template to installation. The workflows include step-by-step approach with tasks and roles identified and assigned. Everything is time-stamped, so there is a complete record of each job, and each activity, from start to finish. Scheduling and tracking include things like the cut schedule (how much they will cut for the day, and in what order).

- No missed steps: Each activity has to be completed before the next activity can start. If something isn’t correct, the issue is noted on the job so everyone has visibility and can address the issue right away.

- Customized views: Each role can set up customizable views tailored to their needs or based on job status.

- Mobile access: The team has mobile access via tablets and smartphones powering real-time updates from field teams. Everyone has the ability to see job status and answer questions from any location.

- Move from folders to digital: Digitized all their customer and project information with job files, photos, work orders, materials/slab inventory, templates, and activities attached to each project for up-to-date job information for the entire team.

The Results

- More efficiency, more capacity: Increased daily production capacity from 600-700 square feet per day to 1,500-1,600 square feet per day with the same 50 person team.

- Significantly reduced errors: Tracking and reporting helps Southeast Stone identify where errors happen. They have refined their processes over time to significantly reduce mistakes and have achieved an industry-leading 1% loss rate.

- Better communication, no delays: Eliminated communication bottlenecks with real-time job status visibility across all team members.

Everyone is accountable: Created complete accountability system with change logs tracking every modification to job details by user and timestamp.

About Southeast Stone

Southeast Stone, located in the Orlando and Central Florida area, has been in business since 1999. They are a stone fabricator and installer and serve the residential, commercial, and hospitality markets. The company has experienced rapid growth from 3 to 50 employees within a few years so they understand the challenges and changes a scaling shop experiences firsthand. They have been a Moraware customer for over twenty years.

Southeast Stone Snapshot

Location

Serve the Orlando and Central Florida area

Job Types

Residential, new construction, commercial, and hospitality

Output

Shop produces 1,500-1,600 square feet daily

Employees

50 employees

Moraware Products

CounterGo (quoting)

Systemize (scheduling)

Years of Operation

25+ years