LET'S TALK SHOP | VIDEO TOUR

How Dominis Stone Scaled Their Fabrication Business with Moraware

Step inside Dominis Stone in Tukwila, Washington, for a behind-the-scenes look at how General Manager Matt Balsley and his team keep projects moving.

In this video tour, you’ll see how they’ve streamlined quoting, scheduling, and inventory management — saving hours on large projects, reducing material costs, and keeping the entire shop running at scale.

Dominis Stone Snapshot

Locations

Three shop locations across Tukwila, WA and the Boise, ID area

Job Types

Residential, Multi-Family, Home Builders, General Contractors

Output

Shop produces 76 jobs per week and 1,500 square feet daily

Employees

35 to 45 employees across all three locations

Moraware Products

CounterGo (Quoting)

Systemize (Scheduling & Job Management)

Moraware Inventory (Slab Ordering & Tracking)

Shop Mascot

Yoda, the Golden Retriever

Inside Dominis Stone: How Moraware powers faster quotes, smarter scheduling, and leaner inventory

DRAWING, LAYOUT & ESTIMATING SOFTWARE

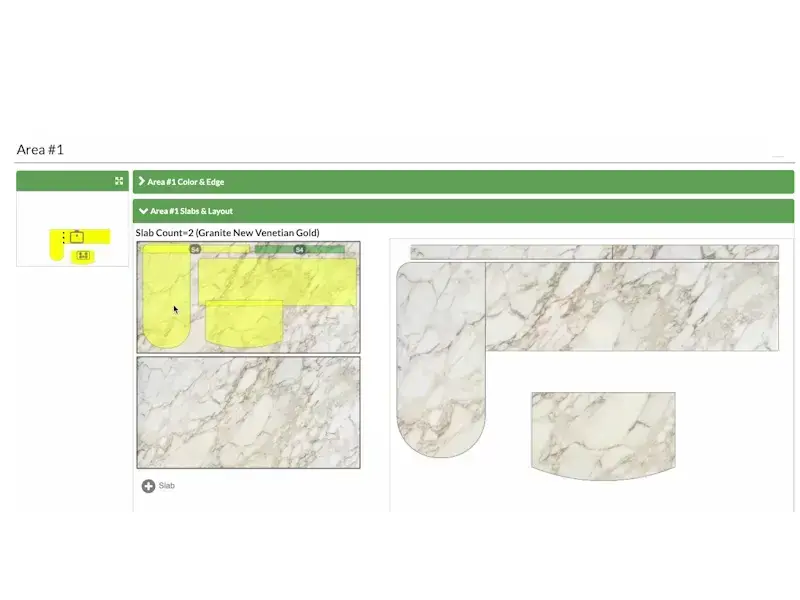

Faster, more accurate quotes with CounterGo

For Dominis Stone, quoting used to be a time-consuming task. What once took 20–30 minutes per job now takes just 5–10 minutes. CounterGo allows their team to move quickly without sacrificing accuracy. On large multi-unit projects, like a 350-unit complex, the time saved adds up to four or five hours.

Beyond speed, the quoting process also helps the team control costs. By laying out pieces directly on slab images, they know exactly how many slabs a job will require — reducing waste and preventing the need to order more material than necessary.

ALL-IN-ONE JOB SCHEDULING & MANAGEMENT

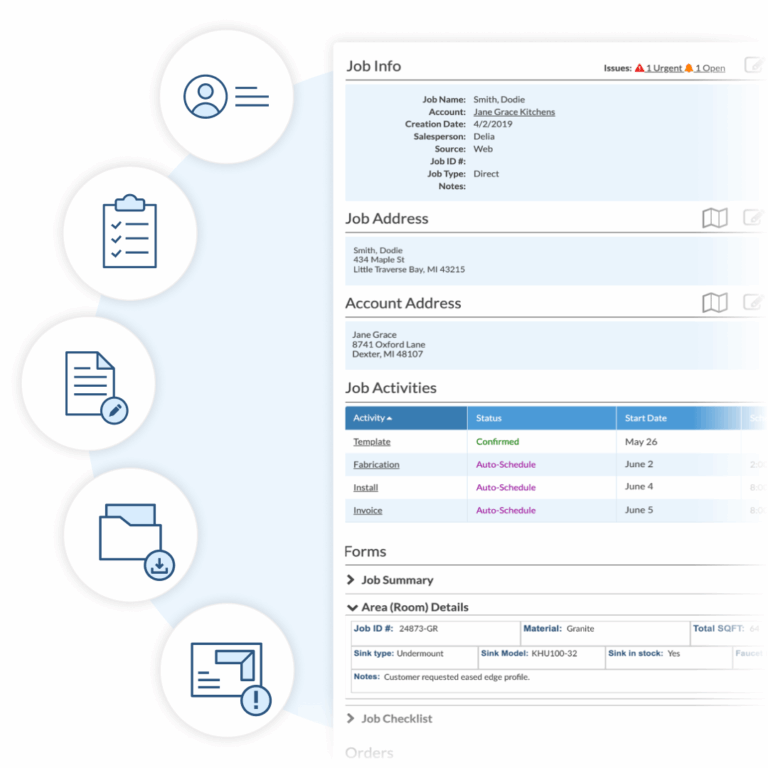

Organized scheduling at scale with Systemize

When a shop is handling 15–20 kitchens or houses every day, keeping schedules straight is a challenge that goes far beyond a shared calendar. For Dominis Stone, the solution was building a workflow around Systemize, adapting it to fit the unique way their business operates.

Today, the software connects all three of their locations, ensuring every employee can access the right information when they need it. From templating and material ordering to install schedules, the entire team can see what needs to get done and when, without the confusion of multiple tools or disconnected spreadsheets.

INVENTORY MANAGEMENT

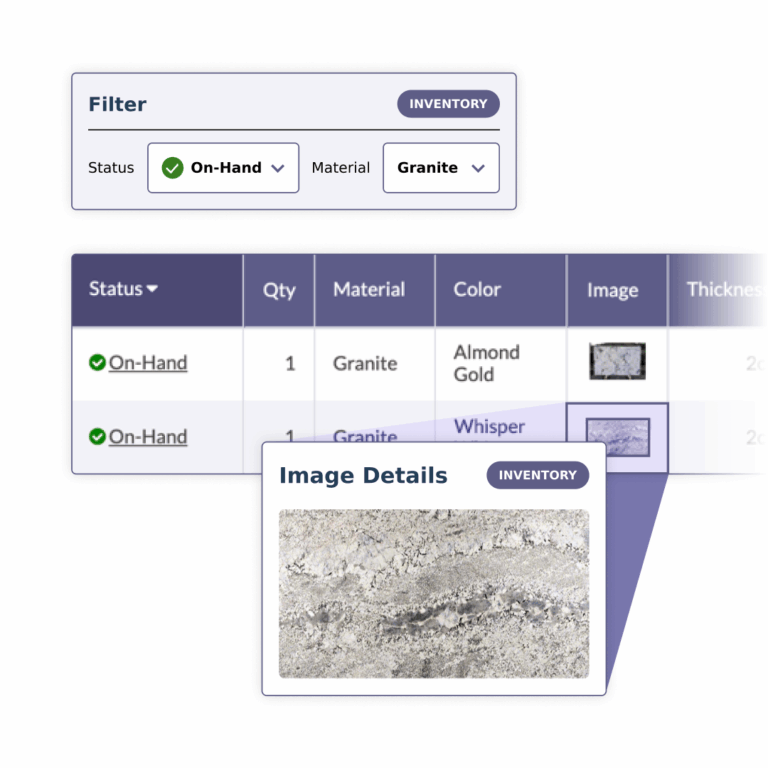

Real savings with Moraware Inventory

For Dominis Stone, inventory used to mean uncertainty and wasted space, with 50 to 100 extra slabs on hand at any given time. By tagging and tracking every slab and sink in Moraware Inventory, they’ve gained full visibility into what’s available, what’s allocated, and when to reorder.

The result: leaner inventory, fewer surprises, and a 10–12% reduction in excess material, saving both money and space.

Summary

- Faster Quoting: Dominis uses CounterGo for quick, accurate quotes, which includes importing slab images, creating a countertop drawing with slab layouts and instant calculations, enabling a 5-10-minute quoting process and saving 4-5 hours per large project.

- Scheduling at Scale: Once the quote is approved the shop relies on Systemize to manage everything from templating, material ordering, to installation scheduling.

- Inventory Management: Moraware Inventory has reduced excess slabs by 10-12%, improving material utilization and saving money, with detailed tracking of slabs and sinks, ensuring better inventory control and cost management.

See how thousands of fabricators like Dominis Stone save hours every week with Moraware

Show off your shop in our video series

Our Let’s Talk Shop video series is all about celebrating fabricators like you—your people, your process, and your shop’s personality. Want to be featured? Fill out the form below.