When one of our first and longest running customers reached out to us with some great feedback about our shop user function, we started chatting and I realized that his experience and new journey towards going 100% paperless was one we could all find value in. Even though Precision Countertops is successfully doing 25,000 jobs a year, they still strive to discover new ways to enhance their processes and systems -sometimes, like in this case, by discovering a feature that hasn’t been utilized before.

So, on that note – I did what I do best and asked Steve Mast of Precision Countertops a million questions. Here are a few of my favorites that I found relatable for our ever-evolving stone industry!

Precision has been a Moraware user since the early days in 2003 and I’ve seen firsthand how thoroughly embedded into your process our software and other technology is. Do you believe it’s necessary to have a structured system in place that utilizes technology in a countertop shop?

I do. I think this is truer now than ever before. When we started using Moraware, technology in our industry was less common. Now, our employees and customers are much more accustomed to technology being a part of their everyday lives.

I think having a defined process is critical in the stone industry because each job is custom made and thus, mistakes are very expensive. In addition to wanting to reduce the amount of costly mistakes, we were conscientious of the fact that remodeling is a big emotional time for our customers.

We needed a defined process that helped to reduce errors so that our customers had an enjoyable experience from start to finish. We had those processes before technology, but they were just more cumbersome and less connected.

Can you pinpoint any major milestones where technology has enhanced your progress?

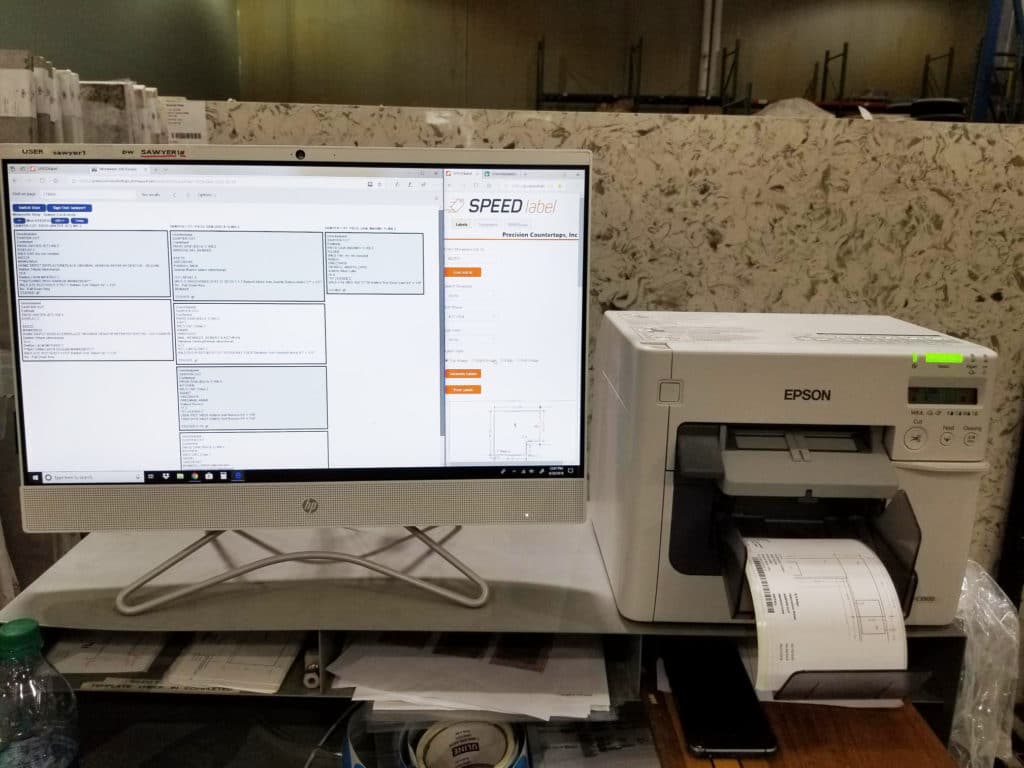

For sure, there are a few “tipping points” in our industry. Many shops I have seen seem to have common denominators in the technology tools they use. Digital templating, which makes it faster and easier. Moraware, which acts as the hub for all touch points to the process. Countergo, which makes quoting much easier with far fewer mistakes. SPEEDlabel for barcoding and labeling of the countertop parts in the shop. Fabrication tooling like saw jet combination and cnc routers.

All of these technology pieces used to be different types of competitive advantages, now it seems as though they are common or necessary to compete. What I see today is the differentiation in how the technology is used, rather than simply the existence of it.

Have you encountered limitations with software as a shop that produces a large volume?

Yes, we have. We have always provided feedback to the technology companies that we work with, but not all of our needs were being met. In those cases, we would develop APIs, or ways in which we could supplement the technology so it met our needs specifically. Most technology these days, like Moraware for example, is very easy to talk to. Machines and software often communicate in a common language, then its just about making those things talk.

I think we can all agree that continuously improving your way of doing things is vital to any business. What are some of the ways you and your team find the pain points in your current process and come up with a solution?

From what I have seen in the past 20 years in the industry, there are two ways to improve and its best to use both. One is to look at a process, sit down with the actual people who do it every day, and just ask them what they would change if they could or what doesn’t make sense to them.

The second way, that is really effective, is to visit other shops and talk with them through associations or shop tours. We try to join or attend various groups like Artisan Group, Rockheads, Natural Stone Institute, SFA, ISFA Baca seminars and Park Digital Expos. We try to attend those meetings when possible and always come away with great new ideas. Then we take those ideas back to our team and see if we can implement them.

Going paperless – what spurred this and why now?

Honestly, we were just tired of printing paperwork and the time it took. Plus the information was not real time. When we started using SPEEDlabel in combination with the shop user function, going paperless was simple and natural. We never had a timeline or goal to be paperless, it just kind of happened and we would never go back.

What’s been the most A-HA! moment you’ve had so far in this transition?

The biggest change for us is to get information about our jobs real time at all times. For example, we didn’t know about the shop user function in Moraware, we saw it last year when we visited The Countertop Factory in Chicago. Even though it’s been available for the last eight years, we just hadn’t seen how effective it could be. Now it’s a fully integrated part of our process that we couldn’t live without.

As a business of your size this must be a huge undertaking, what are the biggest challenges so far?

For us, when adopting a new process with technology it can seem like trying to turn the Titanic. It always takes much longer than we would like. We have to get everyone involved in understanding the change we want to make and get some form of buy in. If it’s an idea from another shop, we will send our associates to see it live in the other shop. That has made the implementation of new ideas much, much easier. If the management team is all bought into the changes, the challenges are far fewer.

Do you think the challenges and solutions you are facing in this transition to paperless are applicable to say, a much smaller shop? Is going paperless a good process for shops across the board?

For sure, I have seen many smaller volume shops go real time by using the shop user function. Frankly, it’s probably easier to set up and implement than for the larger shops. Whether its laser templating, cncs, or labels, I see technology being utilized at every level. With companies like Amazon and Uber being a part of our everyday lives, expectations for countertops and the technology we use to meet those expectations will be the same. Our customers and employees will require it.