In Episode 25, Patrick speaks with Ed Hill of Synchronous Solutions

Listen to this episode to learn:

- The concept of “throughput” vs. square feet and how it can positively impact your bottom line

- In any business process, there is a natural weak link – you must identify this link, called the “natural constraint” and plan around it to improve and optimize

- Why successful companies PLAN for things to go wrong and how to absorb these hiccups

- How to learn more about Synchronous Flow and the Theory of Constraints (hint: read The Goal)

Be sure to subscribe to the podcast in iTunes… and please let us know what you think! You can leave comments for this show on the StoneTalk Facebook page or on this site.

If you have stories or insights that you’d like to share with other fabricators, please reach out to Patrick.

Transcript

Patrick: Welcome to Stone Talk, the podcast for counter top fabricators. Brought to you by Moraware, makers of JobTracker scheduling software and CounterGo estimating software for counter top fabricators. I’m your host, Patrick Foley. Today I’m chatting with Ed Hill, founder of Synchronous Solutions and Synchronous Flow. Let’s give him a call.

Ed: Ed Hill.

Patrick: Hey Ed, Patrick from Moraware, how are you?

Ed: Hey Patrick.

Patrick: Recognizing that I’m not a fabricator, I sell software to fabricators, tell me at a high level, what is Synchronous Flow and why should a counter top fabricator care?

Ed: Synchronous Flow is a modern scientific process flow engineering method. It is a procedure by which we control the flow of information and material through the system.

Patrick: Is this only for large fabricators or any size fabricator?

Ed: It’s for any size company or business of any kind. This is a scientific method that has been utilized in industries of all kinds, of all sizes throughout the world.

Patrick: Okay, let me give a little context then. I know we deal with counter top fabricators and I’ve spoken with many of them, some of whom are your customers who are very big on this concept of Synchronous Flow, specifically for counter top fabricators. So let’s break it down a little bit. One of the main concepts that my customers have used is throughput. Can you explain throughput to me? Is it the same as profit or is it a little bit different?

Ed: It’s very different than profit. Throughput is a measure of value added. It is what is accomplished by an organization, a business, by creating value. An example: If a counter top is sold for, let’s say $5,000, and there are $2,000 worth of material involved in that sale, then the throughput is $3,000. So looking at it this way, you can say that the fabricator invested $2,000 in order to be able to do this job that was just sold and then the shop itself and the installation crew converted that $2,000 to be worth $5,000. So therefore they created $3,000 of value.

And there are two primary reasons we use that metric rather than anything else, rather than sales, rather than square feet, rather than numbers of slabs or any other method. Those two are one, throughput value is highly reflective of the content of the work itself, of the labor content. It’s not exact, but it’s highly reflective.

And the second reason is it is directly related to the financial performance of the company. A given number of sales won’t necessarily produce any profit. A given number of square feet certainly won’t. But a certain number of throughput dollars calculated for that company, once that’s achieved we can be relatively certain that they will make money.

Patrick: Okay, and I think you just answered my next question, was how this relates to fixed costs. So in order for that to be true, what you just said, if I have $100,000 of fixed costs, then after I’ve achieved $100,000 of throughput, then everything else is profit? Am I thinking about that correctly?

Ed: No, not exactly. It’s a little different. All right, well the formula is a sales dollar minus the investment per sales dollar and the material, it’s actually material freight, outsourcing, and commissions are the four items. Not always are they all utilized. Outsourcing would be a counter top fabricator that also did wood and sold wood tops, but they had that fabricated by someone else. So the formula sales dollar minus investment, called truly variable expense, equals throughput. And throughput minus all operating expenses equals profit. So if throughput and outputting expenses are equal then the company’s at break-even.

Now, it’s also important to note that the concept is focused on increasing throughput, not decreasing cost. The comment we make is that the opportunity to increase throughput, to increase value A, to become more productive, to be more effective in the operation is unlimited. But the opportunity to decrease cost is quite limited. And you can’t cut below a certain level, of course. So we don’t focus on decreasing costs, we focus on increasing throughput. I’ll also point out real quickly, Patrick, that we differentiate the two kinds of costs associated in what we call throughput accounting. One is truly variable, and those costs, those expenses, associate directly with having made a sale. And the other is operating expense which is everything else. And therefore the formula is quite simple.

Patrick: That seems really important to me because a lot of our customers ask occasionally about job costing. They want to know, they’ll ask a question something along the lines of, “How can I know if I’ve made a profit on this job?” And I’m not an economist but something about that doesn’t seem right to me because it doesn’t acknowledge that some jobs are going to go to heck, and you’re going to drop a slab, it’s going to be messed up. When you focus on cost, as you said, it seems like you’re chasing a diminishing return. Whereas if you focus on increasing throughput, it’s not so much on one job, it’s on the system as a whole, it’s the aggregate of all the jobs. Am I correct in thinking there’s a limited opportunity to increase throughput for a single job, so what you end up doing is thinking more about the system as a whole, how do I increase throughput over the whole system? Is that true as well?

Ed: Yes, it is. And we call throughput ratio is reflective of how well the company buys materials, being frugal in purchasing, and also minimization of waste. Those two compose the, what we call the throughput ratio and in the counter top industry, a throughput ratio and a solid surface product around 60 percent is good, at 60 percent of the sales dollars throughput, and in granite it goes up to, you know, in the 70 percent range. The engineer stone, quartz stone is typically somewhere between the two. So we manage that, and we therefore know where my starting point is in terms of making a profit.

But you’ve touched on the fixed costs a moment ago, and that’s the important note. In operating expense are all controllable expenses and uncontrollable expenses. We differentiate between those, the uncontrollable occupancy costs, salaries, taxes, things like that, you got to pay whether you produce any tops or not, but the controllable expenses we differentiate, separate those out so that we can project, in a dynamic budgeting concept each month prior to the beginning of the month where we will stand given this projected sales and given this much throughput generated from those sales and it’s provision for how much profit the company plans, budgets for in that month, equals the maximum operating expense that the company can endure for that month. And we separate from that that those expenses which are fixed, which are not controllable, and what that leaves is a really clear line item budget that allows the owner to make some decisions about where to spend money and when to spend money in order to maximize the performance of the company.

Patrick: One other term that you’ve used in there that I’m not sure I understand is “control point”. Where does control point fit into all of this?

Ed: Good question. In a business process, any kind, and counter tops are perfectly suited for this approach, it’s as if that is a chain, a linked metal chain and we all know that the reality of life is that chain pulled strong enough to make it break will only break in one place. And that point is called the constraint. That point is the weakest link in the chain. That point determines the strength of the entire chain. So the first thing we want to do is locate that point. What is the natural constraint in the system? And we work to improve that exploit, there’s a term we use with to increase its productivity, which sometimes moves the constraint, the weak link, from one location to another. And we’re constantly working to identify and optimize that.

But the control point is a little different. The control point can be also the constraint, but it can be a different point. And in the counter top industry, we commonly treat the control point at installation because as we say that’s where the cash register rings. The company doesn’t make money templating or cutting or fabricating, typically. They make money when they install those counter tops in the customer’s location. So almost all the time that’s the control point and sometimes we design, dynamically change the system so that that will also be the constraint and that’s the optimum configuration for utilization of this management approach.

Patrick: So, from a simplistic perspective, if I’m making my reports and things like that, deciding on the control point as installation means I’m probably going to have all my reports based on installation, not necessarily on how much I’ve fabricated, for example. I could have chosen it on how much I’ve templated or fabricated but once I’ve decided that installation is the best control point, then is it simply a matter of focus? When I have a choice between those various things to measure, you know, presumably I’m templating and fabricating about the same amount I’m installing, so I should only focus on one of those.

Ed: Well that’s true. And that’s, you said it well, in summary of this approach, rather than optimizing every step in the process, which can be overwhelming, can be very difficult and chaotic, it often results in an atmosphere of chaos which is what we face when we go into a client company most of the time. By changing that management concept to say, all these things are important but focus your attention here. Beat this like a drum. We call it a drum because we want it on a cadence, methodical and predictable and controllable. And that point is the control point. And imagine, just visualize it, just really steady, consistently, methodically beating all day long. It produces a certain given number of throughput dollars. Again, not square feet or slabs. All other processes, their role is to serve that drumbeat. So no matter where you are, upstream or downstream from that, your goal is to make sure that you feed that process what it needs when it needs it, so it can be constantly beating at a steady pace.

It’s important, another term, it is called protective capacity. And what we’ve designed into the system is some more capacity and all of those non-constraint resources, typically around 15% and the purpose of that is to absorb variability. Murphy lives and we all know that and we try to minimize it, but of course, stuff happens. Slabs break, machines break down, people are absent, all sorts of things happen that cause disruption to the flow. So we know that that happens and we therefore design into the system a capacity to absorb that variability so that drumbeat stays steady. It’s called protective capacity.

Patrick: And basically that’s saying, “I don’t attempt to run my CNC at 100 percent all the time, I leave a little slack in there so that if something happens I can make up for it.” Is that an example of what you’re talking about?

Ed: It is an example, and every piece of equipment which is defined as not a constraint or not a control point needs to have a little bit of that capacity in reserve. It’s utilized, it’s not as if it’s excess and it’s extreme cost, so the contrary, we say that if you don’t plan for that, then you will certainly be bitten by it because things go wrong. We are not in a world of perfection and if you don’t have the ability to absorb those hiccups upstream at any point then they will affect you at the point at where your cash register rings and you don’t want that.

Patrick: Yeah, and so I could make a different decision and say well, my CNC is going to be my control point so I’m going to keep that optimized for that but that would only really be possible if I then had easy way to get additional installers if for some reason the CNC was down for a day and I needed to make up for it. I would need slack somewhere else in the system if I were optimizing for that. Is that true?

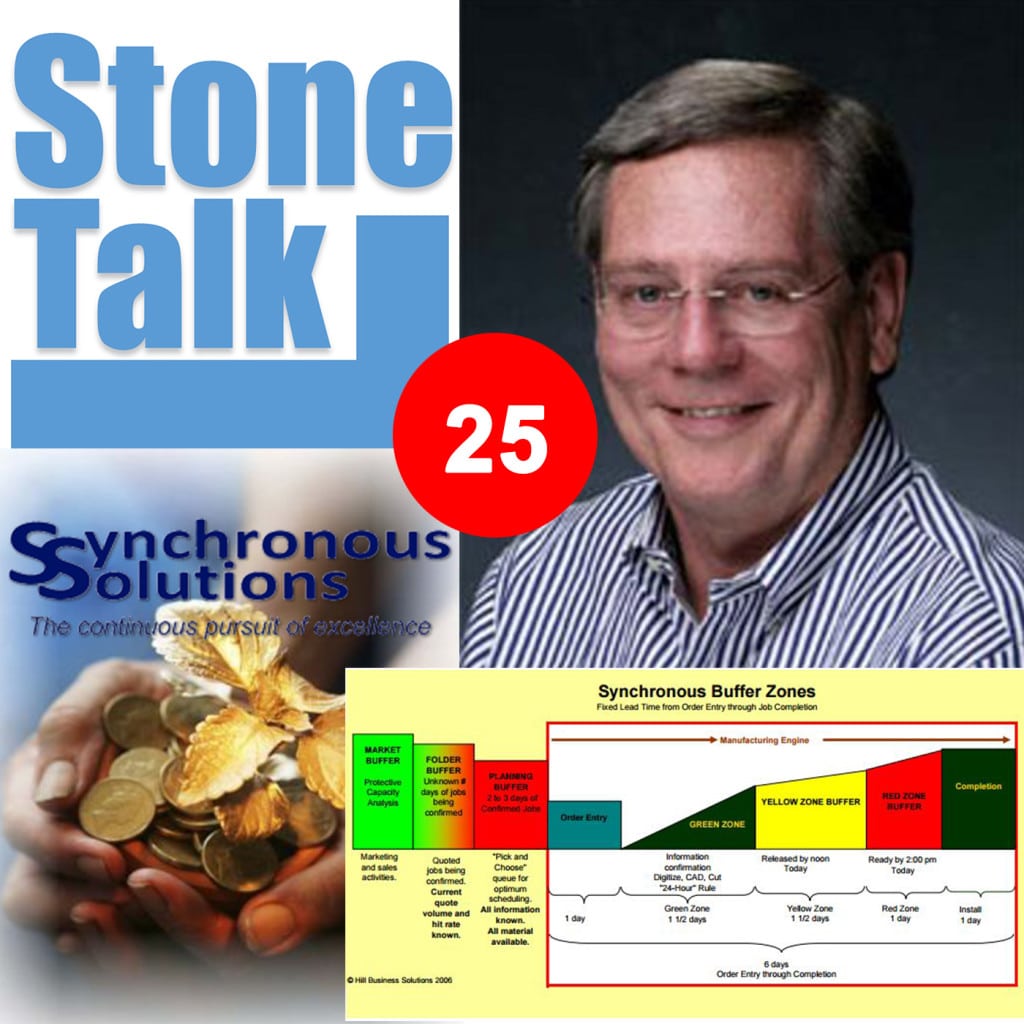

Ed: You do, and we call those items or locations of slack, buffers. We design in buffers throughout the process. Typically in a counter top shop there would be three or four colored zone buffers, and these zones, red, blue, green, yellow, whatever colors we pick typically, are occupied by space and time, and we therefore can control the lead time, the time it takes from template to install is a fixed amount of time, not variable. We control two dimensions in the flow. One is volume, and the other is velocity. Volume is how much, velocity is how fast. The volume is variable, depending upon the demand, depending upon various other factors that affect the flow throughout any day or month. But the velocity part, we want to keep that fixed. We want to set a day, Monday, for example, we template, we want to install the following Monday, that’s a six day process. Monday through Monday, if you count your fingers, that’s actually six days. And we template on Monday and we complete the installation the following Monday. And that time can be shorter than that, it can be three or four days, it can be longer than that, it’s most common that we seek a Monday to Monday or a six day lead time.

Patrick: So on your website, I read a little about buffer management, and I actually had a question about that. So it sounded like you think in terms of daily buffers or shift-based buffers even, where at the beginning of a day, you think in terms of okay, this is what is scheduled for this day. Now, recognizing again, I don’t have experience in manufacturing but the way my brains thinks is more from a To-Do list perspective that I just pick up the last thing that was completed. So for example, if I’m the guy who’s programming the saw, I would just look at the list of templates that have been completed to get the files off my digital templater that are there. Where it sounds like your approach is no, I’m scheduling, the templates happening this day, the program is happening the next day, or a specific shift, etc. First of all, am I understanding that correctly, and second of all, why is it better to schedule or on a shift-wise basis as opposed to just having someone pull off the last item that was completed on the previous step of the workflow?

Ed: It’s a little of both, Patrick. That’s called first-in first-out, so if I’m the programmer following template then I can program only that which was templated so I take the first one that was templated. The buffer concept allows some accumulation in certain locations of numbers of jobs or actually throughput dollars or time and we might change that order depending upon which one is the earliest due date. But it’s different also in that we are really only scheduling one point, we schedule the control point, the template in this case, and possibly also the CNC for example, if that was our literal constraint in the business. And all other functions don’t have a schedule. Those functions basically work first-in first-out but they also take a look at three jobs here, they came in and they order one, two, three but I look at the due date, number three has actually got the earliest date, well I can grab that one. And it therefore leapfrogs the other two, but what I would not do is start, unless I have to, if some emergency, I wouldn’t start one job, get off of it and go to another one only to come back to finish the first one. We try to do them complete through the process.

The objective is to keep product moving. It’s like a mountain river. We want it to flow at a given velocity, there are pools of standing water like in a mountain river that are buffers. And they are timed buffers. Usually a few hours or even as much as one day. And the other zones in the process, we want like white water. We want them moving rapidly through the process so we can optimize the velocity. And that’s a real selling point. Counter tops fabricator sell quality, that’s obviously important, and not even a competitive opportunity because you have to be pretty much perfect. They sell price, they want to be competitive but not necessarily a commodity and you want to be competitive on pricing but the third is a real competitive opportunity and that’s time. If I can be at good quality and reasonable prices, when I’m faster than anybody else then I’m going to get my share of the business.

Patrick: And I would think predictability as well, even as much as being fast, just simply doing it when you say you’re going to do it.

Ed: Absolutely. And as I mentioned, these lead times, the zones from beginning to end, template to install, is fixed. It’s not a variable amount. So yes, we can make a promise when we template on a certain day, assuming all the information is clean and you know how that works, when we need to know the edge and the bowl and the back splash, and all the details we have to know when we enter it into the system. And if that doesn’t change then we know exactly what day it’s coming out.

Patrick: Now does each buffer have a control point? Or is it just one control point for multiple buffers in the system?

Ed: One control point for the plant and probably three or four buffer zones in that plant from beginning to end. Typically every morning we do a buffer management meeting. This is a 15 minute meeting. It’s very agenda driven. If you watch one of these things, it’s almost difficult to understand what’s going on because it happens so rapidly. But the people are used to this. They know what questions the leader is asking, they come prepared to answer those questions, and we do three things. We identify any issues. That’s something that is not in the zone at the point in time that’s supposed to be. We know where everything ought to be every day. And if something is not where it should be, that’s an exception and that comes up. We identify that issue.

Number two, we identify the core cause. What the heck happened? Why is it not where it’s supposed to be? Machine broke down, or was it an operator issue? Was it a material issue? What the heck was it? And so we can address that issue and resolve that immediate issue. And then thirdly we’re identifying a person. So we’re going to say, “Patrick, would you take ownership of this issue?” We hear Patrick say, “Yes, I’ve got it.” Now everybody knows. Patrick’s got that issue and he’s going to deal with it. He isn’t necessarily going to fix it himself, Patrick, but he would make darn sure it got taken care of. And then also over time, we collect all this data in a log book and every month we analyze the data and we say, “Here’s a chronic issue. This thing was the core cause 40 percent of the time that we had issues so let’s go attack that and prevent that fire, rather than continuing to fight it.”

Patrick: That makes a lot of sense, and that reminds me a lot of something we do in the programming world, just a 15 minute stand up at the beginning of the day and again a theme of what, not why. This isn’t the time to dig into performance problems, incentives, issues like that, it’s just identify, “What are we doing today? What did we say we were going to do that we didn’t get done?” To make sure that nothing has fallen between the cracks.

Ed: There you go, that’s the very term we use, we don’t want anything falling between the cracks. We want to make sure it gets addressed and resolved so it’s not a crisis and the earlier we catch it in those zones, the more chance we have to get it fixed before it does become an urgent issue. And as I say, we’re collecting that data to be able to a statistical analysis of it over time and address the things that are chronic.

Patrick: So let’s say I’m a fabricator who wants to get started with synchronous flow. What’s the first step? How do I get started with this? Is it a reading exercise? Is it a “Get in contact with you and do consulting?” How do I get going on this if this is something I’m interested in?

Ed: There’s a book that I strongly recommend, called “The Goal” by Dr. Eli Goldratt. This is actually quite a famous business book. It was written in the early eighties. It was applied in industries of all kinds around the world. I was at Clemson University for a number of years and I worked with Dr. Goldratt on several projects and got into this research with him. That is a book, it’s a novel, it’s a story about Alex who runs a business. It’s an easy book to read. People who read it say, “You know, I think they were writing about me.” And it’s an excellent book, written as a novel so it’s a good story to tell. And that’s what people should do. The owners, maybe business leaders, should read that book. And it’ll probably excite them about a different way to look about how to run their business. And of course, they’re always welcome to give me a call. The articles, the items on my website, many of them apply specifically to the counter top industry. So that would be another source of information.

I might also point out it before we leave it is that it is important to tie this concept into the existing software and Moraware is excellent. When I go to a place that doesn’t have software, and there aren’t very many anymore, some still use spreadsheets, I always recommend Moraware because it’s very compatible and it has worked well with synchronous flow in development over the years.

Patrick: Well, thank you. So, one thing you mentioned on your website is that once you get going, each key person starts thinking in terms of throughput more than even say square feet, and yet I know that so many of the fabricators I talk to still kind of fall back on square feet. Is it, in your experience, working with fabricators who really embrace synchronous flow, do they make the shift of square feet to throughput for their key metrics?

Ed: People tell me, among my clients, that they go to conferences, meetings across the country, and they tend to gather in groups of people who understand what throughput is, and they speak that language. And I’ve had folks call me to say, “You know, I’ve stumbled upon a group of guys at a cocktail party or a conference and they were talking this language which I didn’t understand and I ended up getting your name and they asked me to call you.” So yes, it’s different terminology and the industry is entrenched in square feet, in most companies, that’s everything. And it does require that people think differently. My best example is a typical job of 40 square feet that has an eased edge and it’s quite a simple counter top. Another one exactly the same shape, exactly the same square feet, but it has a mitered edge, a laminated edge, or some complicated configuration. They’re exactly the same square feet. And if you manage by square feet and put that second one in the plant the day after the first one, you’d see a dramatic difference in productivity. Using throughput dollars we negate that difference and the amount of the dollars going through the plant is what’s leveled or optimized, not square feet. Makes a big difference.

Patrick: Yeah, and as you say in the simple, the light hasn’t completely flipped on for me, but it’s beginning to go from off to slightly dim at least. I like the term, “the value created.” Because that does seem like a clearer goal to me. The goal isn’t square feet for the sake of square feet, it’s the overall value that I’m generating as a business. So I’m still thinking in terms of maximization that makes more sense than square feet. I don’t completely grasp it but I’m getting there.

Ed: Let me give you one more. We’ve seen plenty of companies that produce a lot of square feet, but they’re struggling to make any money. And on a given day or a given month, depending on the mix of product. And at other times they say, “Gosh, I was so surprised, we had a good month, I don’t know what happened. We did okay, but I wish I knew what I did right.” Well, the problem is that they’re measuring square feet and the value created can be very, very different. By focusing on a given number of dollars, in calculating, we know we need this many throughput dollars created. How do we know that? Well, we’ve got a tool that calculates that. That starts with providing a market demand and does some math to calculate the throughput. And then it says at that given level of sales, then here’s the operating expense limit that you must stay within.

Now we know what the numbers are, we know what the numerator is, we know what the denominator must be. And if we can control that, every day of a 20 to 22 day month, and know what it is every day, we know what the goal is every single day, day 1 through day 20. And we know where we stand on that goal because we keep track of that every day, all the way through the month, then we’re not going to be surprised when the financial statement comes out next month, because we have controlled it during the month.

Patrick: Well that does make sense to me and I’m going to keep digging into it because customers ask us for help with their software but in our opinion they don’t really care about our software, they care about their business. So the better we can understand why they’re creating reports, not just how to create them, but what they’re going after, the better we can help them. So I’m going to keep digging into that and trying to understand it, so I appreciate your help on that. One last question before we go, has the idea of synchronous flow for you, has it evolved over the last decade or so? Or are the principals you’re dealing with so constant that the last customer you talked to this month is no different from the first one you talked to ten years ago?

Ed: No, it’s constantly evolving. DuPont got me into this business in 1995, I think it was. I met Dr. Goldratt in 1988, ’87 at Clemson. The first projects we did back in there, early-mid 90s are nowhere close to what we’re doing these days. The science continue to develop. It’s being developed academically in several institutions around the country. It’s being developed by folks like me and my group of people who’ve been applying at a number of industries. And in the counter top industry it has been enormous application. There’s been a lot of development in this industry over these last 10 or 15 years particularly.

It’s a very fine tuned process for the counter top industry right now. Many of the tools have been customized for that industry. Now, I say all that to tell you that it has continued to develop and it has been applied specifically to this industry, but at the same time I’ll tell you that every single counter top fabricator I’ve been in, and that’s over 50 now, they’re all different. There’s not any two alike. Even in a company that has more than one site, they’re different. So the tool, the concept that we apply in a business is tailored for that company, and what they need, and the approach that they use, customized.

Patrick: Interesting. Well, again this is super interesting stuff, I know we just barely scratched the surface today, but I’m going to keep exploring and learning myself and I encourage anyone listening to this to read that book you mentioned and to reach out to you. And as people reach out to us, we’ll continue to learn more and perhaps get you back on in a few months, and dig into the next level. So, thank you for helping all our customers and adding success to this industry because when one of us figures out how to do this better, ultimately all of us succeed. And we want our customers to succeed so that we can keep succeeding obviously. And we appreciate the contribution you’ve made to that.

Ed: Well you’re really welcome, thank you for the time, I appreciate it.

Patrick: All right, and by the way, I had to say, I apologize, I cringed when you said Clemson because I’m a Notre Dame fan.

Ed: Oh, no. It was a great game.

Patrick: It was great game. It really was. Painful loss, but you know, it would’ve been a painful loss for Clemson, too. It was criminally conservative play calling by Clemson in that last ten minutes. They sat on that lead. I wanted them to pay for it, but they held on. They won. Anyway.

Ed: And Notre Dame, I’m telling you, that was a come back.

Patrick: It was a good fight.

Ed: If you had made that two point conversion, who knows. It could’ve gone either way.

Patrick: Thought it was going to be one for the ages, but it was just a good game.

Ed: Yeah, me, too.

Patrick: Anyway, I’m glad you enjoyed it.

Ed: All right Patrick, well I did too.

Patrick: Have a good day.

Ed: Alright, thanks.

Patrick: Bye bye.

Thanks for listening to Stone Talk, the podcast for counter top fabricators. If you liked this episode, be sure to visit stonetalk.org or subscribe to Stone Talk in iTunes for more. Visit the Stone Talk show Facebook page to join in the conversation and follow @stonetalkshow on Twitter. Stone Talk is brought to you by Moraware, makers of JobTracker scheduling software and CounterGo estimating software for counter top fabricators. I’m your host, Patrick Foley, and I look forward to spending time with you again on the next episode of Stone Talk.