Last week, Kathleen and I dusted off our cowgirl boots and headed to Dallas, TX for the Stone Industry Education summit. Okay, I lied. I don’t have boots… but Kathleen does!

These educational series by Natural Stone Institute and Stone World Magazine are incredibly beneficial to fabricators and sponsors alike. We attended as sponsors and a resource for fabricators but I’m still impressed by how much knowledge I took away with me from the one-day event.

Being smart about growth

Eric Tryon gives a great talk. And as a team member of a company experiencing growth, I really enjoyed this segment of his presentation. Possibly my favorite summation of this was from a fabricator in the audience when asked what he’s looking to gain from the event. “I want to grow, I want to kick butt, and I want balance.” I mean, can I get a “yeehaw!” He’s so right.

Sidenote: If you’re the fabricator who said this, you are awesome and I have about 50 more questions for you so get in touch!

When you’re looking to grow into a kick-butt shop, while maintaining a healthy balance, you’ll need to be efficient and safe with your growth process. Eric spoke on the importance of defining roles and skills, understanding your customer expectation, tracking your growth, and our favorite topic of conversation – bottlenecks.

“You are in the PEOPLE business”

If you are thinking, “But wait, I’m in the countertop business. Am I reading the wrong article?” then I can totally understand why you’re confused. But, Eric explains that hiring and training are critical elements to your countertop business. If you want to do more jobs successfully and efficiently, you’ll need to invest in your people.

He recommends putting the skills you are looking for on paper and looking for someone who checks those boxes. By avoiding the quick-fix hire and taking time to understand what skills are necessary for producing quality work, you’ll avoid costly mistakes and wasted time.

Another great point that really struck me was Eric’s discussion about onboarding new employees. Hiring and training the right people will perpetuate good habits for future employees. You don’t want a person who doesn’t meet their goals or follow your set processes teaching your new employees those habits.

Tracking what matters

Now that you’ve got the right people in your shop, how do you know if you’re making progress? We’re talking data, people! Every shop is different and it’s up to you to sit down and figure out what data it is that you need. This data should show you what is working in your shop and what is holding you back so that you can make changes and grow.

There is software and technology available to help with this. (We just might know of some great software if you’re asking…) By using the right tools for your shop, you can track your results and make changes as needed. You may need a process for measuring your employee’s success or need data that reports how many square feet a week you are producing. Whatever your need is, find the best tool to help you consistently analyze and make changes. This will help you grow smartly and efficiently.

Let’s work smarter, not harder

As a marketing nerd, automation and efficiency are two of my favorite topics. As a Moraware employee, talking about bottlenecks is my other favorite topic. So, when Eric said, “Doing work and making money are not the same thing,” I might have been nodding too emphatically.

The first step to lean manufacturing is to find the bottlenecks in your process. By focusing on improving the productivity of your shop’s processes, you’ll be able to find those pain points and find solutions that will allow you to grow. For example, here at Moraware we hear a lot about bottlenecks in the quoting process. Inconsistencies in pricing or quote turnarounds? Anyone facing these bottlenecks would purchase an estimating software like CounterGo to help them keep their quotes professional, fast, and accurate.

As you grow, you’ll solve one bottleneck and then find another one. It’s really important to remember that this is a constant motion, as Eric says. Maybe you purchased new equipment or changed a step in your installation process, and now your bottleneck is that you want more sales because you can handle way more jobs now. Sounds like a good problem to have!

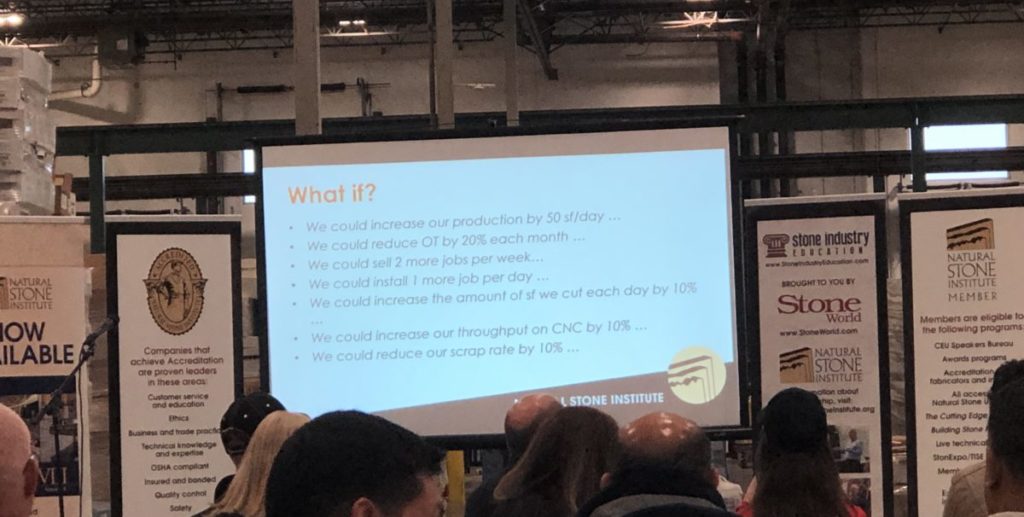

Just remember to always be tracking, measuring, and analyzing your data to keep up with your productivity. Eric recommends utilizing the “What Ifs” and asking yourself what you could be doing and then finding a solution to make those a reality.

A great industry to be a part of

Throughout the day, the friendly atmosphere only furthered my belief that one of the best, and most unique, traits of our industry is the willingness to share. “We’re here to share, learn, and grow together” is such a common attitude at every event and throughout many of the industry resources. If you haven’t attended one of these events near you, I highly recommend checking out their schedule and registering for one!

Do you have any estimating or scheduling bottlenecks? We’re here to help! Sign up for a free demo and have a conversation with us about how to improve your processes.