Slab layouts make or break accurate estimates. Some fabricators guess, others manually crunch square footage numbers, and many spend hours in CAD. None of these are ideal solutions for quick, reliable slab layouts that you can show the customer to help close the sale.

The CounterGo slab layout feature solves this problem. Here’s how to end your slab layout headaches.

Inaccurate Layouts Cost Thousands

When you meet a new prospect interested in new kitchen countertops, you calculate the square footage and determine one slab is needed. You provide your quote, and they send back a deposit.

Then fabrication starts. The veining won’t match no matter how you position it. Do you proceed and hope they don’t notice? Risk a costly remake? Or go back and explain you need a second slab, nearly doubling the price?

Most fabricators have been burned by underestimating material needs and either having to eat the cost or having a touch conversation with the customer.

A quick, professional slab layout during estimating avoids this scenario by:

- Ensuring you have enough slabs for the job.

- Adding a professional-looking drawing on your quotes which boosts your reputation and customer experience.

- Identifying when extra slabs are necessary upfront.

Visual Slab Layouts Win More Jobs

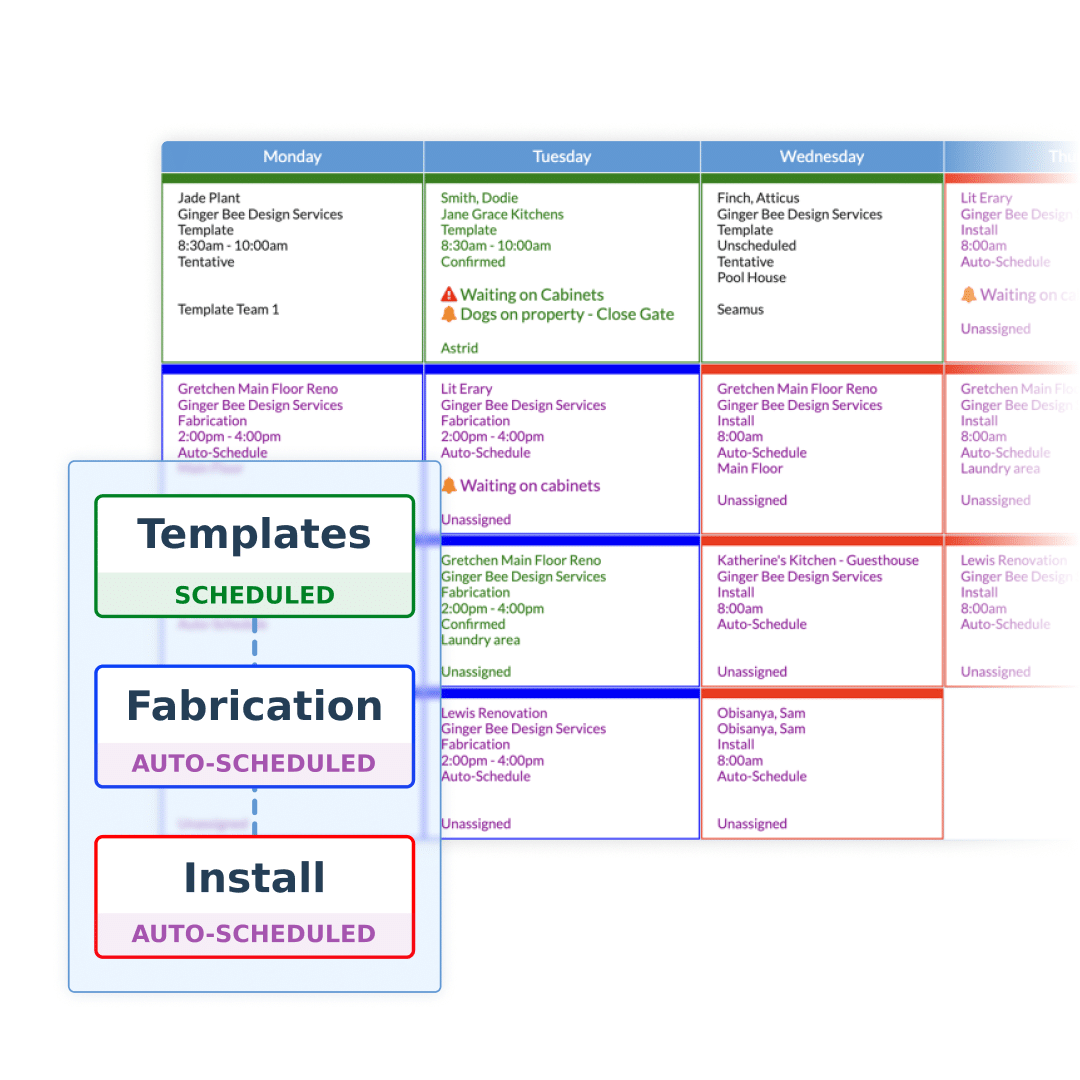

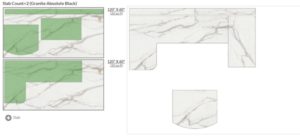

In a competitive industry, a superior customer experience wins new business. CounterGo’s slab layout feature allows you to add images of the slab to your design. The software overlays the slab image onto the countertop, letting you drag and match veining and seams.

You can show this to your potential customer as you create the quote (which only takes 3 minutes, start to finish). When customers see how slabs fit their design, you’re more likely to close the deal, especially if your competitors work manually.

Jennifer Boles at Nelson Tile & Stone explains:

“Moraware allows us to take a picture and import it into the system. It really helps clients see what their piece is going to look like and gives them confidence that we’re going to bring something out that will fit well together.”

Watch her full story:

Use Visuals, Not Words, to Close Deals

Showing a customer what their finished countertop will look like with speed and accuracy helps you look more professional and reduces potential miscommunication or errors with customers.

Explaining complex stone installations can be challenging and time-consuming. With a tablet, you can show customers exactly how pieces will fit together, communicating the information in a few minutes.

Pricing discussions are smoother when customers can see the work involved. Visual demonstrations make it easy to explain why two slabs work better than one, whether it’s poor fit, mismatched veining, or aesthetic issues. Customers who might initially resist the additional cost often understand immediately once they see the comparison.

Why Not CAD or Hand Drawing for Slab Layouts?

For fabricators who aren’t using CounterGo, the most common ways to do a slab layout include manual calculations, hand drawing or using cardboard templates, or CAD.

Perhaps the best option out of these is CAD. CAD addresses vein alignment but requires hours of work. Why waste labor time on prospects who might not buy? Early in quoting, you need quick yet accurate solutions. Slabs cost thousands, so going back to customers with wrong estimates creates unhappy clients and lost profits.

CounterGo’s Slab Layout Feature

CounterGo is built for estimating. The slab layout feature is a valuable bonus that saves fabricators time every day and improves their close rates because they get the right number of slabs on their estimate from the start. The software is simple and easy to use and delivers accurate material estimates in minutes. When we demo the slab layout feature, fabricators are excited to see they can draw countertops, lay them on slabs, and generate accurate prices, and send professional quotes in a few clicks.

To check out CounterGo for yourself, set up a demo by clicking here!

Read More: